Precision CNC Milling Services

for Complex, High-Quality Parts

Get Quality CNC Milling Projects from Shenandoah Machine & Maintenance

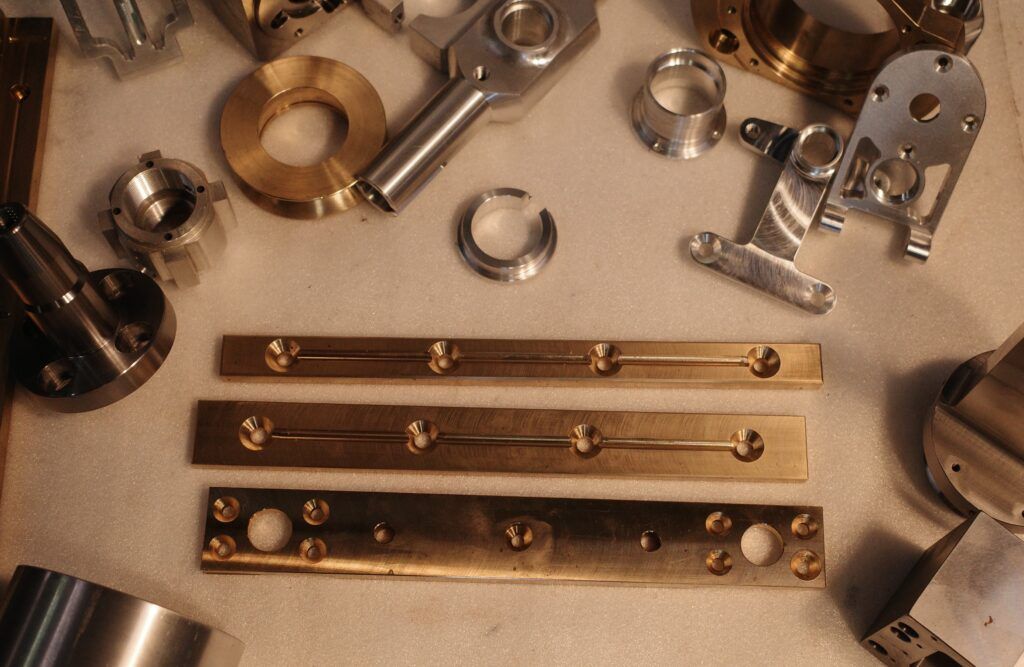

At Shenandoah Machine & Maintenance, we proudly offer precision CNC milling services designed to deliver exceptional accuracy, repeatability, and quality for a wide range of industries. CNC, or computer numerical control machining, uses automated, high-speed cutting tools to form designs from metal or plastic stock. Our shop is equipped with TRAK TMC 10, TRAK TMC 12, TRAK TMC 14 milling machines—versatile, reliable equipment capable of producing both simple and highly complex geometries. Whether you need a single prototype or a full production run, we deliver custom machined parts tailored to your exact specifications.

State-of-the-Art CNC Milling Equipment to Meet Demanding Standards

Our CNC milling machines include 3-axis and 4-axis mills capable of tackling a variety of part sizes and complexity levels. With Mazak QT18 turning centers and ProtoTrak lathes supporting our production, we have the capacity to handle turning and milling operations under one roof. CNC milling allows us to precisely remove material using rotating cutting tools, following programmed tool paths derived from your CAD models. Whether the cutting tool moves while the workpiece stays fixed, the workpiece moves while the tool stays stationary, or both move simultaneously, we achieve tight tolerances and flawless finishes.

Custom CNC Milling for Diverse Industries Across the U.S.

We proudly serve industries including aerospace, medical, military, energy, transportation, agriculture, marine, packaging, and custom manufacturing. Our CNC milling expertise supports applications from aerospace brackets and engine components to medical implants, precision housings, and machine parts. Each part we mill undergoes rigorous quality control checks to ensure conformance to specifications and industry standards. Clients across Roanoke, VA, Lynchburg, VA Salem, VA, Christiansburg, VA and beyond trust us for custom CNC machining services Made in the USA with integrity and precision.

Versatile CNC Milling Capabilities for Metals and Plastics

At Shenandoah Machine & Maintenance, we mill a wide range of materials, including aluminum, carbon steel, stainless steel, tool steel, alloy steel, titanium, copper, brass, bronze, Inconel, thermoplastics, ABS-like materials, acrylic, and polyurethane. Our machinists have deep expertise selecting the right feeds, speeds, tooling, and fixtures for each material to achieve optimal results. Whether you’re machining lightweight aluminum aerospace parts or corrosion-resistant stainless steel components for marine applications, we provide precision CNC milling services that meet demanding specifications.

CNC Milling with Consistent Accuracy and Repeatability

Every part produced in our shop benefits from computer-controlled precision and highly skilled machinists who monitor the process at every stage. Using CNC milling for custom metal and plastic parts, we maintain tight tolerances down to thousandths of an inch, delivering parts that fit and function as intended in their final assemblies. By combining advanced programming with our TRAK and Mazak machines, we minimize manual error while increasing production efficiency and part consistency.

Prototyping and Low-Volume Production with CNC Milling

Our CNC milling services are ideal for prototyping, low-volume production, and custom one-off projects. We work closely with engineers, designers, and procurement teams to turn CAD models into functional, manufacturable parts. Prototypes allow for testing form, fit, and function before committing to higher production volumes. Whether you’re developing a new medical device, aerospace component, or industrial machine part, our CNC milling ensures your prototypes are accurate and production-ready.

High-Volume CNC Milling Production Runs with Fast Turnaround

In addition to prototypes and small batches, we provide CNC milling for high-volume production runs. Our machines are programmed to produce repeatable, identical parts over large quantities, saving customers time and reducing per-unit costs. We use modular fixtures and tooling strategies to minimize setup times, ensuring faster turnaround without sacrificing precision. Industries that rely on bulk precision components, such as energy, defense, and transportation, benefit from our efficient production capabilities.

Your Trusted Partner for CNC Milling and Machined Components

When you partner with Shenandoah Machine & Maintenance for CNC milling services, you’re working with a company built on integrity, precision, and Made in the USA quality. We combine state-of-the-art machines, experienced machinists, and rigorous quality control to deliver parts that exceed expectations. Whether you’re located in Virginia or across the U.S., we provide custom CNC milling services with fast turnaround and competitive pricing. Contact us today to request a quote and learn how we can support your next machining project with precision and reliability.