CNC Turning Services

Built for Precision and Flexibility

Take Care of Your CNC Turning Needs with Shenandoah Machine & Maintenance

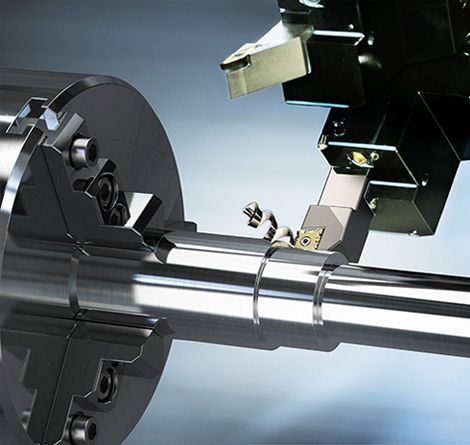

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. At Shenandoah Machine & Maintenance, we proudly offer precision CNC turning services, and CNC lathe machining solutions for industries requiring tight tolerances and high-quality finishes. Our skilled machinists use advanced turning centers to create parts efficiently while maintaining exceptional accuracy.

Custom CNC Turning for Complex Geometries and Multiple Materials

A turret with tooling attached, is programmed to move to the bar of raw material and remove material to create the programmed result. This process, known as “subtraction machining,” allows us to machine intricate designs. We provide CNC turning and milling, custom CNC turning, CNC turning company, and CNC turning shop to meet diverse customer requirements across sectors like aerospace, automotive, energy, and medical. By combining turning and milling in one setup, we minimize handling and increase part complexity options.

Versatile CNC Turning Capabilities for All Shapes and Sizes

The starting material, though usually round, can be other shapes such as squares or hexagons. Depending on the bar feeder, the bar length can vary. This affects how much handling is required for volume jobs. Our CNC turning, CNC turning stainless steel, CNC turning aluminum, CNC turning brass, CNC turning copper, CNC turning titanium capabilities allow us to handle a wide range of metals and materials for various industries. We tailor each job to the specific material properties and dimensional requirements.

Live Tooling and Dual-Spindle CNC Turning for Enhanced Functionality

CNC lathes or turning centers have tooling mounted on a turret that is computer-controlled. The more tools that the turret can hold, the more options are available for complexities on the part. CNC turning for aerospace, CNC turning for medical parts, CNC turning for the energy industry, and CNC turning for automotive manufacturers depend on these flexible machining options to meet performance standards. CNC’s with live tooling services can stop the bar rotation and add additional features such as drilled holes, slots, and milled surfaces—saving time and reducing setups.

Advanced CNC Turning Centers with Single and Dual Spindles

Some CNC turning centers have one spindle, allowing work to be done all from one side, while other turning centers have two spindles—a main and sub-spindle. A part can be partially machined on the main spindle, moved to the sub-spindle, and have additional work done on the other side in this configuration. We utilize CNC dual spindle turning, CNC lathe with live tooling, CNC bar feed turning, and CNC turning for complex parts to tackle multi-operation parts efficiently while maintaining tight tolerances and minimizing operator intervention.

Evaluating the Best Fit for CNC Turning Applications

There are many different kinds of CNC turning centers with various types of tooling options, spindle options, outer diameter limitations, as well as power and speed capabilities that affect the types of parts that can be economically made on it. CNC turning small diameter parts, CNC turning large diameter parts, and CNC turning custom components allow us to tailor solutions based on size, material, and production volume. We work closely with customers to determine if CNC turning is the optimal process or if other machining methods are better suited.

Is My Part a Good Fit for CNC Turning?

While many factors go into determining if a part can be made most cost-effectively on a specific CNC turning center, some key questions include: How many parts are needed short-term and long-term? CNC turning centers are generally good for prototypes to short-run volumes. For high-volume small-diameter parts, Swiss screw machines might be a better option. Our CNC turning prototypes, and CNC turning production services help clients balance cost, lead time, and machining complexity for the best outcome.

Request Your CNC Turning Quote Today

At Shenandoah Machine & Maintenance, we proudly serve industries that require reliable, high-precision turning services. We’re here to deliver when you need:

- CNC Turning Services

- Precision CNC Turning

- Custom CNC Turning

- CNC Lathe Machining

- CNC Turning for Aerospace

- CNC Turning for Medical Parts

- CNC Turning for the Energy Industry

- CNC Turning for Automotive

Contact us today to request a quote and learn how our expertise can support your next machining project with Made in the USA quality and precision.